Description

Due to their excellent characteristics, titanium ball valves are widely sought after. Especially in the automotive, aviation, shipping and PTA industries, titanium ball valves are favored for their strength, corrosion resistance, and portability. Weidouli specializes in custom-designed hand operated valve for added safety and reliability.

| Ti Alloy Valves Specification List | ||||||

|

Material

|

Titanium | |||||

| Seal Material | PTFE/ RPTFE | |||||

| Working Pressure | 1.6 – 6.4Mpa | |||||

| Working Temperature | -29°C — +180°C | |||||

| Availabe Size | 1/2″-4″,(DN15-DN100) | |||||

| Available Connection | BSP/ BSPT/ NPT/ Flanged/ Welded | |||||

| Nominal Pressure | P10/PN16 | |||||

| Operation | Manual,Pneumatic, Electric | |||||

| Suitable Medium | Water,Sewage,Seawater,Gas,Food,Oils,etc | |||||

| Standards | GB9112,DIN2501,BS4504,ISO2084,ANSI125 | |||||

| Applications | Water, Oil, Gas, | |||||

| Nominal Diameter | DN40-DN300 handle lever | |||||

| DN350-DN1200 gear box | ||||||

| Operation Temperature | -10°C~150°C | |||||

|

Titanium

Valves Chemical Composition

|

||||||

|

Grade

|

Ti | C | Fe | H | N | O |

| Ti Grade 2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max |

|

Alloy Ti Valve

Mechanical Analysis

|

||||||

|

Density

|

Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | ||

| 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20% | ||

Corrosion Resistance Characteristics of Titanium Ball Valves

- Titanium ball valves is almost no corrosion in the atmosphere, freshwater, seawater, high-temperature water vapor.

- Titanium ball valves and titanium valves are very resistant to corrosion in alkaline media.

- Titanium ball valve has strong anti-ion ( Cl ) ability and excellent resistance to ion corrosion.

- The corrosion resistance of the titanium ball valves in the reducing acid depends on whether the medium has a corrosion inhibitor

- Lightweight, high mechanical strength, wide application, military field.

- Seawater Desalination

- Pulp and Paper

- Petrochemical industry

- Smelting

- Aviation and Military

Technical Specification

Design Standard: API, ASME, EN, ISO, JIS, DIN, BS, GB

Connection type: Flange, Wafer, SW, NPT, BW

Pressure range: 150LB~1500LB, 1.0MPa~25.0MPa, JIS10K~100K

Size range: NPS3/8”-32”, DN10~DN800

Drive: Lever, Gear, Electric, Pneumatic actuator

Design Feature:

Resilient seal or Metal to metal seal

Full bore or Reduce bore

Fire safe design, Anti-static device, Blow-out proof stem,

Double block and bleed function

Grease injection for seat & stem

Cavity pressure self-relief

Optional lockable device

Anti-leakage design packing & packing box

ISO 5211 mounting pad

The surface form a protective film after Hard face treatment for trim. It not only improves anti-corrosion performance, but also can open and close easily because of improved surface hardness.

Main Part Material :

Titanium Gr2、Gr3、Gr5、Gr6、Gr7、Gr12

Titanium GrC2、GrC3、GrC5、GrC6、Ti-Pd7B、GrC12

Titanium GrF2、GrF3、GrF5、GrF6、GrF7、GrF12

Features

API 6D designFire-safe Certified API 607

Blowout-proof stem

Adjustable Stem packing, anti-static device

Integral ISO mounting pad for actuation

Integral locking device

NACE to MR-01-75

Options

Body Material: WCB, A105, LF2, LCC & 316SSSeat Material: Reinforced teflon, Viton, Devlon, Nylon or Peek

Ball Material: 316, 304, LF2 & A105+ENP

Other material available upon request

Standards

ANSI B16.34ANSI B16.10

ANSI B16.5

MSS SP-25

API 598

API 607

API 608

API 6FA

Note: Gear operators recommended for 8" and larger

RP Ball Valve

150 LB

Dimensions: inches (millimeters)

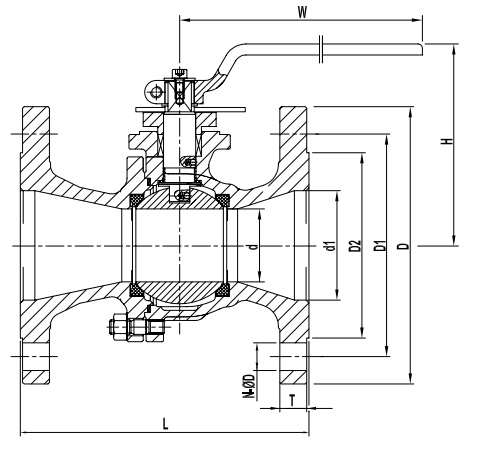

| Sizes | d | d1 | L | D | D1 | D2 | T | N-ØD | H | W |

|---|---|---|---|---|---|---|---|---|---|---|

| Inside Bore Diameter | Inside Flange Diameter | Face to Face | Outside Diameter of Flange | Bolt Circle | Outside Diameter of Raised Face | Flange Thickness | No. of Holes / Hole Diameter | Center to Top | ||

| 3/4" X 1/2" | 1/2 (13) | 3/4 (19) | 4-19/32 (117) | 3-15/16 (100) | 2-3/4 (70) | 1-11/16 (43) | 13/32 (10) | 4-Ø5/8 (16) | 3-1/4 (82) | 6-1/4 (160) |

| 1" X 3/4" | 3/4 (19) | 1 (25) | 5 (127) | 4-11/32 (110) | 3-1/8 (79.5) | 2 (51) | 7/16 (11) | 4-Ø5/8 (16) | 3-1/4 (84) | 6-1/4 (160) |

| 1-1/4" X 1" | 1 (25) | 1-1/4 (32) | 5-1/2 (140) | 4-17/32 (115) | 3-1/2 (89) | 2-1/2 (64) | 7/16 (11) | 4-Ø5/8 (16) | 4-1/8 (105.5) | 7-1/8 (180) |

| 1-1/2" X 1-1/4" | 1-1/4 (32) | 1-1/2 (38) | 6-1/2 (165) | 4-15/16 (125) | 3-7/8 (98.5) | 2-7/8 (73) | 1/2 (13) | 4-Ø5/8 (16) | 4-1/8 (105.5) | 7-1/8 (180) |

| 2" X 1-1/2" | 1-1/2 (38) | 2 (50) | 7 (178) | 6 (150) | 4-3/4 (120.5) | 3-5/8 (92) | 9/16 (14.5) | 4-Ø3/4 (19) | 4-5/8 (118) | 9 (230) |

| 3" X 2" | 2 (50) | 3 (75) | 8 (203) | 7-1/2 (190) | 6 (152.5) | 5 (127) | 11/16 (17.5) | 4-Ø3/4 (19) | 5 (126) | 9 (230) |

| 4" X 3" | 3 (75) | 4 (100) | 9 (229) | 9-1/16 (230) | 7-1/2 (190.5) | 6-3/16 (157) | 29/32 (22.5) | 8-Ø3/4 (19) | 6-1/8 (154.5) | 14-1/8 (360) |

| 6" X 4" | 4 (100) | 6 (150) | 10-1/2 (267) | 11 (280) | 9-1/2 (241.5) | 8-1/2 (216) | 15/16 (24) | 8-Ø7/8 (22) | 7-5/8 (192) | 17-3/4 (450) |

| 8" X 6" | 6 (150) | 8 (201) | 11-1/2 (292) | 13-1/2 (345) | 11-3/4 (298.5) | 10-5/8 (270) | 1-1/16 (27) | 8-Ø7/8 (22) | 10 (255) | 27-1/2 (700) |

* Does not include 1/16" raised face in the 150lb and 300lb standards.

* Dimensions are based on most recent drawing revisions and are subject to change without notice.

300 LB

Dimensions: inches (millimeters)

| Sizes | d | d1 | L | D | D1 | D2 | T | N-ØD | H | W |

|---|---|---|---|---|---|---|---|---|---|---|

| Inside Bore Diameter | Inside Flange Diameter | Face to Face | Outside Diameter of Flange | Bolt Circle | Outside Diameter of Raised Face | Flange Thickness | No. of Holes / Hole Diameter | Center to Top | ||

| 3/4" X 1/2" | 1/2 (13) | 3/4 (19) | 6 (152) | 4-1/2 (115) | 3-1/4 (82.5) | 1-11/16 (43) | 9/16 (14.5) | 4-Ø3/4 (19) | 3-1/4 (82) | 6-1/4 (160) |

| 1" X 3/4" | 3/4 (19) | 1 (25) | 6-1/2 (165) | 4-15/16 (125) | 3-1/2 (89) | 2 (51) | 5/8 (16) | 4-Ø3/4 (19) | 3-1/4 (84) | 6-1/4 (160) |

| 1-1/4" X 1" | 1 (25) | 1-1/4 (32) | 7 (178) | 5-5/16 (135) | 3-7/8 (98.5) | 2-1/2 (64) | 11/16 (17.5) | 4-Ø3/4 (19) | 4-1/8 (105.5) | 7-1/8 (180) |

| 1-1/2" X 1-1/4" | 1-1/4 (32) | 1-1/2 (38) | 7-1/2 (190) | 6-7/64 (155) | 4-1/2 (114.5) | 2-7/8 (73) | 3/4 (19.5) | 4-Ø7/8 (22) | 4-1/8 (105.5) | 7-1/8 (180) |

| 2" X 1-1/2" | 1-1/2 (38) | 2 (50) | 8-1/2 (216) | 6-1/2 (165) | 5 (127) | 3-5/8 (92) | 13/16 (21) | 8-Ø3/4 (19) | 4-5/8 (118) | 9 (230) |

| 3" X 2" | 2 (50) | 3 (75) | 11-9/64 (283) | 8-1/4 (210) | 6-5/8 (168.5) | 5 (127) | 1-1/16 (27) | 8-Ø7/8 (22) | 5 (126) | 9 (230) |

| 4" X 3" | 3 (75) | 4 (100) | 12 (305) | 10-1/32 (255) | 7-7/8 (200) | 6-3/16 (157) | 1-1/4 (30.5) | 8-Ø7/8 (22) | 6-1/8 (154.5) | 14-1/8 (360) |

| 6" X 4" | 4 (100) | 6 (150) | 15-7/8 (403) | 12-19/32 (320) | 10-5/8 (270) | 8-1/2 (216) | 1-3/8 (35) | 12-Ø7/8 (22) | 7-5/8 (192) | 17-3/4 (450) |

| 8" X 6" | 6 (150) | 8 (201) | 16-1/2 (419) | 15 (380) | 13 (330) | 10-5/8 (270) | 1-9/16 (40) | 12-Ø1 (25) | 10 (255) | 27-1/2 (700) |

* Does not include 1/16" raised face in the 150lb and 300lb standards.

* Dimensions are based on most recent drawing revisions and are subject to change without notice.

Titanium alloy Valve

| Titanium Trunnion Ball Valve | grade 2 titanium Pinch Valve |

| titanium steel alloy Swing Check Valve | gr 2 titanium Reducing Valve |

| titanium steel Angle Control Valve | titanium grade 5 Ball Valve |

| titanium grade 2 Globe Valve | ti grade 5 Butterfly Valve |

| titanium grade 5 Needle Valve | grade 5 titanium Gate Valve |

| ti grade 5 Y Type Control Valve | grade 2 titanium Plug Valve |

| grade 5 titanium Cryogenic Valve | Titanium Diaphragm Valve |