Description

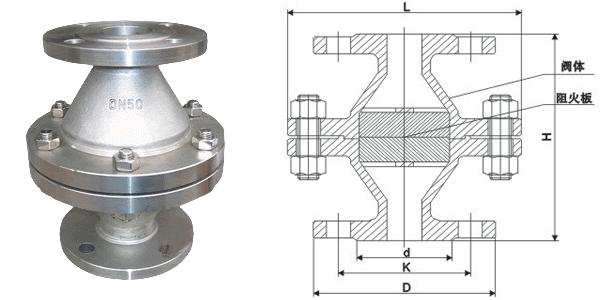

GZW pipeline flame arrester

Pipeline explosion-proof flame arrester is a safety device used to prevent the spread of flammable gas and liquid flame and to prevent backfire from causing an explosion. It is usually installed on pipelines that convey or discharge flammable and explosive gases. Such as torches, heating combustion systems, petroleum gas recovery systems or other flammable gas systems.

Flame arresters are widely used in pipelines for heating fuel gas, natural gas, and liquefied petroleum gas, as well as systems for oil and gas recovery, coal mine gas emissions, gas analysis, etc., which can effectively ensure the safe operation of gas pipelines and gas use points. The function of the pipeline flame arrester is to prevent the flame spread of combustible gas and flammable liquid vapor and to prevent backfire from causing an explosion. It is usually installed on the fuel gas main line in front of the furnace. It is usually a short pipe with a larger diameter than the fuel gas line and flanges at both ends. In the pipe, about ten pieces of copper wire mesh are installed perpendicular to the airflow. The thick cast aluminum ring compresses the periphery of the mesh and forms a certain interval. Due to the excellent heat dissipation performance of the copper mesh, when the flame encounters the copper mesh, the flame will be extinguished due to a sharp drop in temperature, thereby playing the role of fire resistance. Its main function is to allow the passage of flammable and explosive gases and prevent suffocation of the flames introduced into the storage tank from the outside. This kind of pipeline flame arrester can be used under low temperature conditions in high-cold areas, and it can be matched with the snorkel or used alone. It is suitable for storage of Class A oil products with a flash point of less than 28℃ and Class B oil products with a flash point of less than 60℃. It is also suitable for storage materials on dome tanks with nitrogen topped. The principle of gravel flame arrester and net flame arrester Same as above for pipes.

Pipeline explosion-proof flame arrester is designed and manufactured by applying the principle of extinguishing due to heat loss when the flame passes through the narrow pores of the thermal conductor. The pipeline explosion-proof flame arrester is mainly composed of two parts: a shell and a filter element. The shell should have sufficient strength to withstand the impact pressure generated by the explosion. The corrugated filter element is supported by stainless steel, copper-nickel alloy, aluminum or aluminum alloy. The corrugated flame arrestor can organize the violent flame of deflagration, and can withstand the corresponding mechanical and thermal effects, has low flow resistance, and is easy to clean and replace.

Performance and characteristics of pipeline flame arrester:

The flame arrester has reasonable structure, light weight, corrosion resistance, and qualified explosion resistance performance. It can stop the fire every time with the subsonic flame test for 13 consecutive times.

The flame arrester is easy to overhaul and easy to install. The burning resistance is qualified, and there is no tempering in the burning test for 1 hour.

The flame arrester core is made of stainless steel, which is corrosion-resistant and easy to clean. The shell water pressure test is qualified.

Applicable scope of pipeline flame arrester:

Flame arresters are suitable for pipelines, Class A, oil products, hydrogen-oxygen liquefied products with flash points below 28°C and kerosene, diesel, toluene crude oil with flash points below 60°C, pipelines for conveying flammable gases, and flare series , Oil and gas recovery system, heating furnace fuel gas pipeline network, gas purification system, gas analysis system, coal mine gas discharge system.

Main performance of pipeline explosion-proof flame arrester:

1. The anti-explosion performance is qualified, and 13 consecutive anti-explosion performance tests can prevent the fire each time. 2. The burning resistance is qualified, and there is no tempering in the burning test for 1 hour. 3. The shell water pressure test is qualified. Reasonable structure, light weight and corrosion resistance. Easy to check and repair, easy to install.

Working principle of pipeline explosion-proof flame arrester:

Regarding the working principle of flame arresters, there are currently two main views: one is based on heat transfer; the other is based on the wall effect.

Principles of pipeline explosion-proof flame arrester repair and maintenance:

1). The flow direction mark on the flame arrestor must be consistent with the flow direction of the medium.

2) In order to ensure that the performance of the flame arrester meets the purpose of use, before installing the flame arrester, you must carefully read the instructions provided by the manufacturer and carefully check whether the label is consistent with the requirements of the installed pipeline.

3). Check once every six months. Check whether the fire barrier is blocked, deformed, or corroded.

4) The blocked fire barrier should be cleaned to ensure that each hole is unblocked, and the deformed or corroded fire barrier should be replaced.

5) When cleaning the core of the flame arrester, use high-pressure steam, non-corrosive solvent or compressed air to purge, and do not use sharp hardware scrubbing.

6) When reinstalling the fire barrier, the gasket should be updated and the sealing surface should be clean and free from damage, and no air leakage should be allowed.

What are the ten prohibitions of flame arresters in chemical companies?

One: Factory

No drinking or snacking; no bringing children; no private work; no slippers or leather shoes; no chatting for fun; no reading non-business books; no leaving posts, shifting posts, sleeping posts; no unauthorized work Shift shifts and types of work; no non-working clothes or vests are allowed to work; no shawls and long hair are allowed to work.

Two: Production area

Strong open flame management, smoking is not allowed in fire and explosion-proof areas. Vehicles without a flame arrestor are not allowed to drive in the no-fire zone. During working hours, it is not allowed to sleep, do private work, leave work, and do things that have nothing to do with production. Drinking is not allowed before or in class. It is not allowed to use gasoline and other highly volatile combustibles to scrub equipment, utensils and clothing. Do not wear labor protection equipment (including work clothes, work shoes, work caps, etc.) in accordance with factory regulations and are not allowed to enter production positions. Equipment with incomplete safety devices is not allowed to be used. The equipment not in charge of oneself is not used. If safety measures are not implemented when overhauling the equipment, the overhaul is not allowed. The equipment after shutdown for maintenance is not allowed to start without thorough inspection

Share flame arrester parameters

1. Drive mode: automatic;

2. Working temperature: -20℃+425℃;

3. Valve body material: cast iron, cast steel, stainless steel, 304, 304L, 316, 316L, etc.

4. Connection method: flange, thread;

5. Manufacturing standards: national standard GB, JB, HG, American standard API, ANSI, British standard BS, Japanese JIS, JPI, etc.;

6. Working pressure: 1.6MPa-6. 4MPa;

At present, people know that flame arresters are more commonly used in gas discharge systems. In fact, there are many uses for flame arresters, but they are usually not paid attention to. Flame arrestor is also called fire arrester, mainly because its function is to prevent flames from entering inflammable and explosive equipment or to prevent flames from spreading. In fact, to put it bluntly, a flame arrestor is a safety device. The development of science and technology nowadays has also brought new equipment to meet people's increasing demands. The flame arrester is also constantly updated and improved, striving to exert greater effectiveness.

Material of pipeline flame arrester parts:

|

Body material |

Carbon steel WCB, stainless steel 304, 316 |

|

Firestop core material |

Stainless steel explosion-proof and fire-resisting corrugated board |

|

Seal material |

Oil-resistant asbestos rubber, PTFE |

|

Ambient temperature ℃ |

≤480 |

|

Nominal pressure (MPa) |

0.6~5.0 |

|

Explosion-proof level |

BS5501: ⅡA, ⅡB, ⅡC |

Pipeline flame arrester national standard flange connection dimensions:

GB, JB

|

Specification |

Installation size (mm) |

||||

| D | K | DL | H | N-∅d | |

| DN20 | 105 | 75 | 130 | 160 |

4×14 |

| DN25 | 115 | 85 | 135 | 160 | 4×14 |

| DN32 | 135 | 100 | 155 | 180 | 4×18 |

| DN40 | 145 | 110 | 170 | 200 | 4×18 |

| DN50 | 160 | 125 | 195 | 220 | 4×18 |

| DN65 | 180 | 145 | 220 | 220 | 4×18 |

| DN80 | 195 | 160 | 250 | 250 | 8×18 |

| DN100 | 215 | 180 | 295 | 260 | 8×18 |

| DN125 | 245 | 210 | 360 | 300 | 8×18 |

| DN150 | 280 | 240 | 430 | 360 | 8×22 |

| DN200 | 335 | 295 | 520 | 420 | 12×22 |

Pipeline flame arrester American standard flange connection dimensions:

ANSI, API, ASME are available for JIS standards

|

Specification |

Installation size (mm) |

||||

| D | K | DL | H | N-∅d | |

| 3/4" | 98 | 70 | 130 | 160 | 4×15 |

| 1” | 108 | 79.5 | 135 | 160 | 4×15 |

| 1-1/4“ | 117 | 89 | 155 | 180 | 4×15 |

| 1-1/2” | 127 | 98.5 | 170 | 200 | 4×15 |

| 2“ | 152 | 120.5 | 195 | 220 | 4×19 |

| 2-1/2” | 178 | 139.5 | 220 | 220 | 4×19 |

| 3“ | 190 | 152.5 | 250 | 250 | 4×19 |

| 4” | 229 | 190.5 | 295 | 260 | 8×19 |

| 5“ | 254 | 216 | 360 | 300 | 8×22 |

| 6” | 279 | 241.5 | 430 | 360 | 8×22 |

| 8“ | 343 | 298.5 | 520 | 420 |

8×22 |