Description

PTFE Lined Ball Check Valve

Meet design specification as per B 16.34 / Face to Face as per ANSI B 16.10 / Flange dimensions as per B 16.5

Testing Standard as per BS-EN 12266-1 / DIN-EN588 -1

Lining Standard as per ASTM F 1545

Ball Check valves have a hydraulically optimized design. The lining thickness (4.5mm) offers very high permeation resistance

The Full port design is engineered to minimize pressure drop and other improved flow characteristics

Can be installed either vertically and dependent up on application horizontally as well

Inside body with full lining guide for ball, guided ball for better sealing in horizontal position

A minimum differential pressure of 1 Bar is necessary so that the ball is pressed in to seat

Ball is properly shut off on soft seat sealing

Hollow Ball can also used for low opening differential pressure

The Valves are suitable for liquids, vapour, gas, corrosive hazardous, pure hot highly permeating media

Technical Details :

Optional Features :

“O”-Ring design available for Gas application for tight shut off.

Large sizes on request

Material

| No. | Part | Cast Iron | Cast Steel | Stainless steel |

Stainless steel |

||

| Z | C | P | R | PL | RL | ||

| 1 | Body/Bonnet | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Disk/Stem | 35 | 1Cr13 | 1Cr18Ni9 | 1Cr18Ni12Mo2Ti | 00Cr18Ni10 | 00Cr17Ni14Mo2 |

| 3 | Lining / Seat | PCTEF(F3),FEP(F46),PFA(F4),PP,PO | |||||

| 4 | Bolt | WCB | 1Cr17Ni2 | 1Cr18Ni9Ti | |||

| 5 | nut | PTFE(F4) | CF8 | CF8 | |||

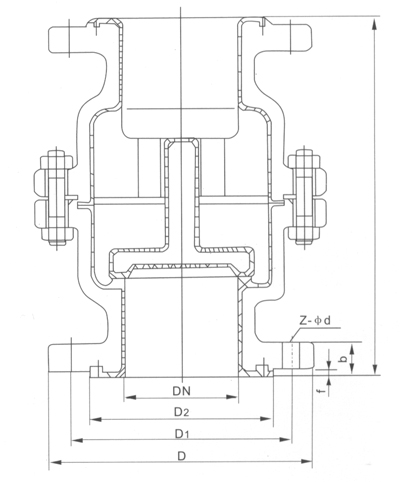

| Size | L | D | D1 | D2 | f | b | Z-φd | |

| DN(mm) | NPS(inch) | PN1.0MPa | ||||||

| 15 | 1/2 | 108 | 95 | 65 | 45 | 2 | 14 | 4-φ14 |

| 20 | 3/4 | 117 | 105 | 75 | 55 | 2 | 16 | 4-φ14 |

| 25 | 1 | 127 | 115 | 85 | 65 | 2 | 16 | 4-φ14 |

| 32 | 5/4 | 140 | 135 | 100 | 78 | 2 | 18 | 4-φ18 |

| 40 | 3/2 | 165 | 145 | 110 | 85 | 3 | 18 | 4-φ18 |

| 50 | 2 | 203 | 160 | 125 | 100 | 3 | 20 | 4-φ18 |

| 65 | 5/2 | 216 | 180 | 145 | 120 | 3 | 20 | 4-φ18 |

| 80 | 3 | 241 | 195 | 160 | 135 | 3 | 22 | 4-φ18 |

| 100 | 4 | 292 | 215 | 180 | 155 | 3 | 22 | 8-φ18 |

| 150 | 6 | 356 | 280 | 240 | 210 | 3 | 24 | 8-φ23 |

| 200 | 8 | 495 | 335 | 295 | 265 | 3 | 26 | 8-φ23 |

| 250 | 10 | 622 | 390 | 350 | 320 | 3 | 28 | 12-φ23 |

| 300 | 12 | 698 | 440 | 400 | 368 | 4 | 28 | 12-φ23 |

| 350 | 14 | 787 | 500 | 460 | 428 | 4 | 30 | 16-φ23 |

| 400 | 16 | 914 | 565 | 515 | 482 | 4 | 32 | 16-φ25 |

| 450 | 18 | 978 | 615 | 565 | 532 | 4 | 32 | 20-φ25 |

| 500 | 20 | 978 | 670 | 620 | 585 | 4 | 34 | 20-φ25 |

| PN1.6MPa | ||||||||

| 15 | 1/2 | 108 | 95 | 65 | 45 | 2 | 14 | 4-φ14 |

| 20 | 3/4 | 117 | 105 | 75 | 55 | 2 | 16 | 4-φ14 |

| 25 | 1 | 127 | 115 | 85 | 65 | 2 | 16 | 4-φ14 |

| 32 | 5/4 | 140 | 135 | 100 | 78 | 2 | 18 | 4-φ18 |

| 40 | 3/2 | 165 | 145 | 110 | 85 | 3 | 18 | 4-φ18 |

| 50 | 2 | 203 | 160 | 125 | 100 | 3 | 20 | 4-φ18 |

| 65 | 5/2 | 216 | 180 | 145 | 120 | 3 | 20 | 4-φ18 |

| 80 | 3 | 241 | 195 | 160 | 135 | 3 | 22 | 8-φ18 |

| 100 | 4 | 292 | 215 | 180 | 155 | 3 | 24 | 8-φ18 |

| 150 | 6 | 356 | 280 | 240 | 210 | 3 | 28 | 8-φ23 |

| 200 | 8 | 495 | 335 | 295 | 265 | 3 | 30 | 12-φ23 |

| 250 | 10 | 622 | 405 | 355 | 320 | 4 | 32 | 12-φ25 |

| 300 | 12 | 698 | 460 | 410 | 375 | 4 | 34 | 12-φ25 |

| 350 | 14 | 787 | 520 | 470 | 435 | 4 | 38 | 16-φ25 |

| 400 | 16 | 914 | 580 | 525 | 485 | 4 | 40 | 16-φ30 |

| PN2.5MPa | ||||||||

| 15 | 1/2 | 108 | 95 | 65 | 45 | 2 | 16 | 4-φ14 |

| 20 | 3/4 | 117 | 105 | 75 | 55 | 2 | 16 | 4-φ14 |

| 25 | 1 | 127 | 115 | 85 | 65 | 2 | 16 | 4-φ14 |

| 32 | 5/4 | 140 | 135 | 100 | 78 | 2 | 18 | 4-φ18 |

| 40 | 3/2 | 165 | 145 | 110 | 85 | 3 | 18 | 4-φ18 |

| 50 | 2 | 203 | 160 | 125 | 100 | 3 | 20 | 4-φ18 |

Applications :