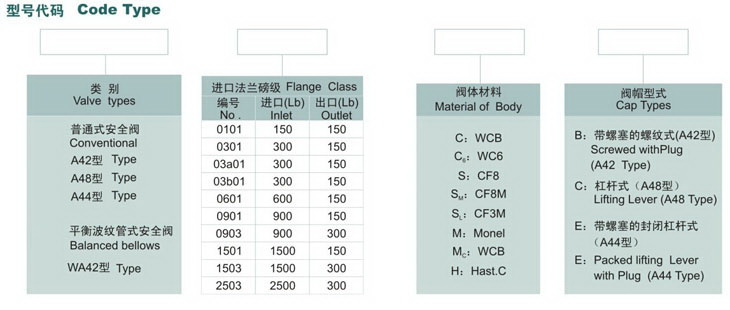

Description

API 526 Pressure Relief Valves

Performance:

The allowable tolerance of the set pressure: <+/-3% of the set pressureOverpressure:<10% of the set pressure

Blowdown:<15% of the set pressure

Tightness: the valves have good seat tightness, conforms to API527

Features:

1)The solid nozzle screws into the body. its maintenance is easy2)The shape of the disc holder has been designed to enhance the effect of the fluid thrust for an instant lift of the disc

3)Blowdown control is provided with adjustable nozzle ring only

4)The adequate materials and clearance between disc holder and guide, spindle and adjusting screw assures disc to lift successfully.

5)The surface of both the disc and the nozle seat is depsited with STL. Excellent flatnes and surface finish of the seating surfaces by precision machining and lapping assure safety valve to have high degree of seal tightness and long usage

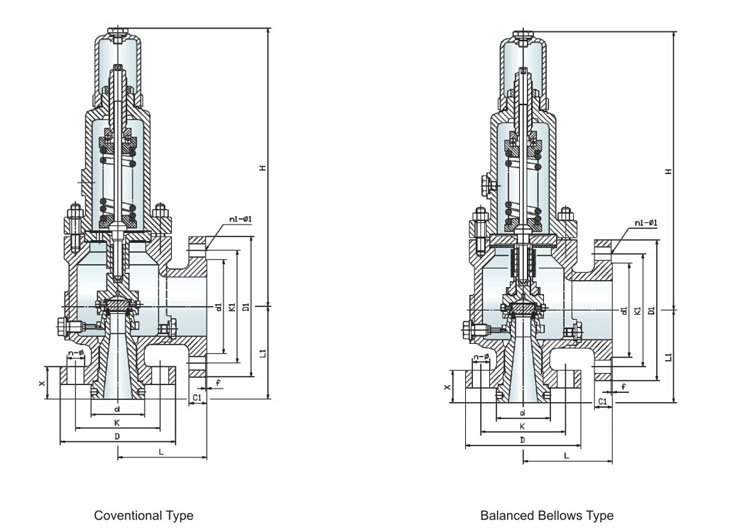

6)The bllows of balanced bellows safety valve not only can avoid and effect of variable back pressure in the system, but also can protect spring and other trim components from corrosive media

7) The choice of material is careful. The manufacture of the spring and the bellows has strict technological process. Each of them is tesed and checked strictly.

Specifications

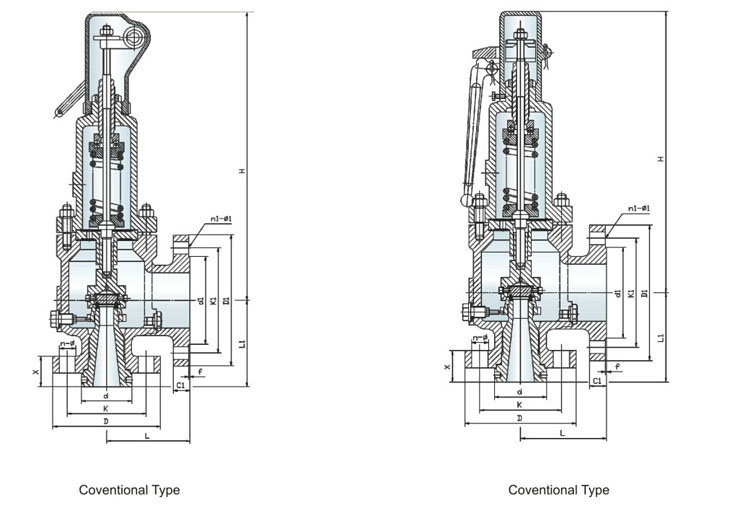

Conventional type Safety ValveSafety Valve/pressure safety valve, angle type

full lift safety valve

Conventional type, Standard safety valve for fluids and gas

metal to metal seated

Flanged connection acc. to ANSI B16.5

Applications

Provided as safety device for protection against excessive pressure in pressure vessels.Approved for gases, vapours and fluids

Working temperatures: Lower than 300°C

Standards Compliance

Design and Manufacture: API RP 520Face to Face(end to end): API 526

Test and Inspection: API 527

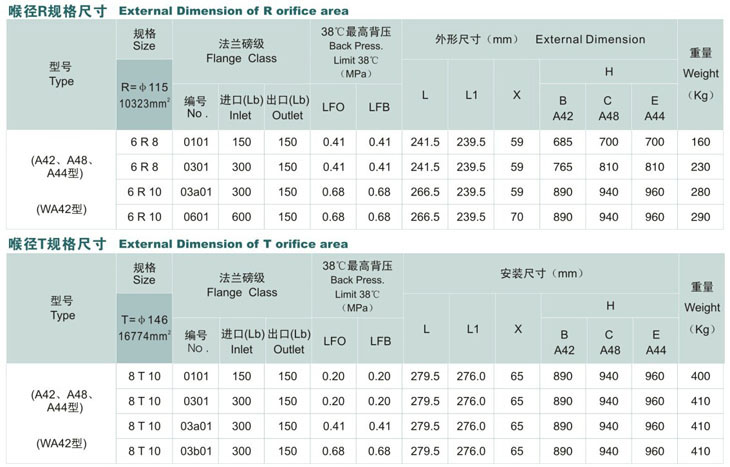

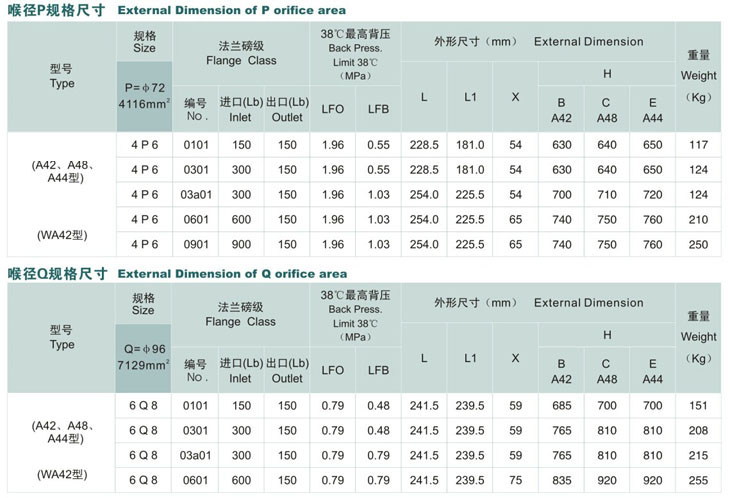

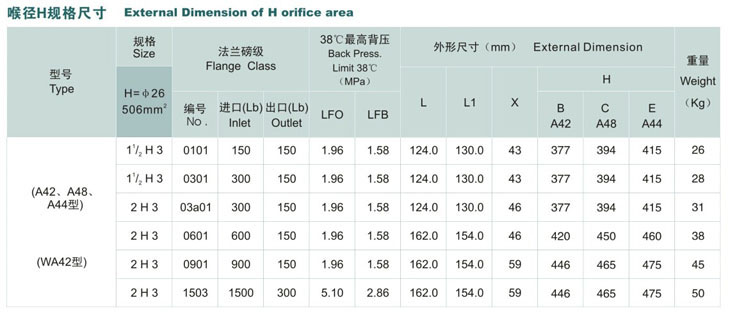

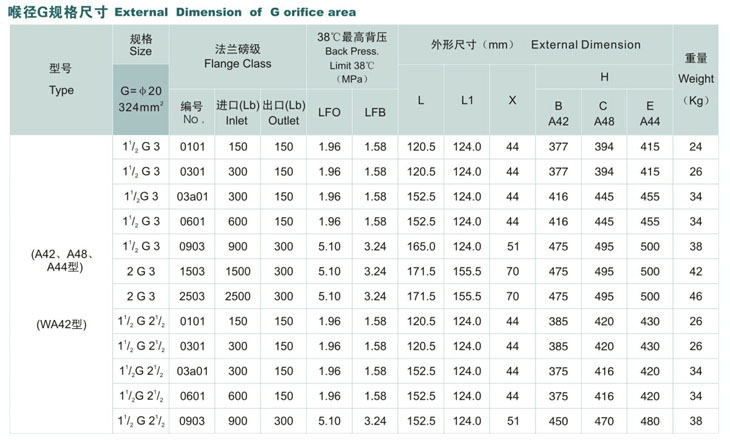

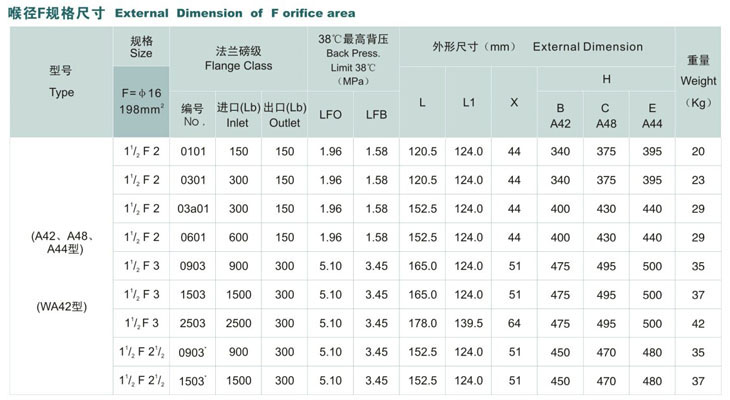

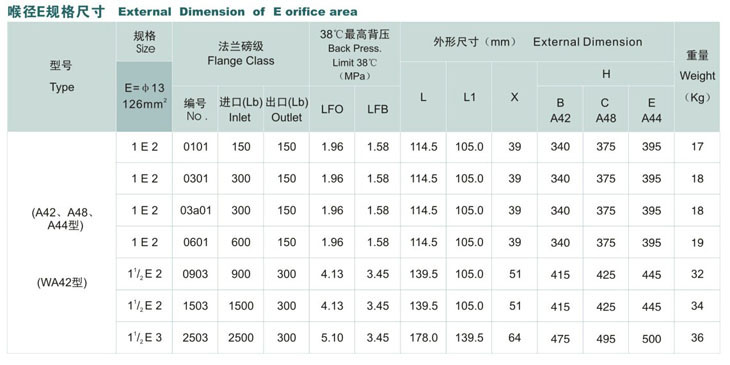

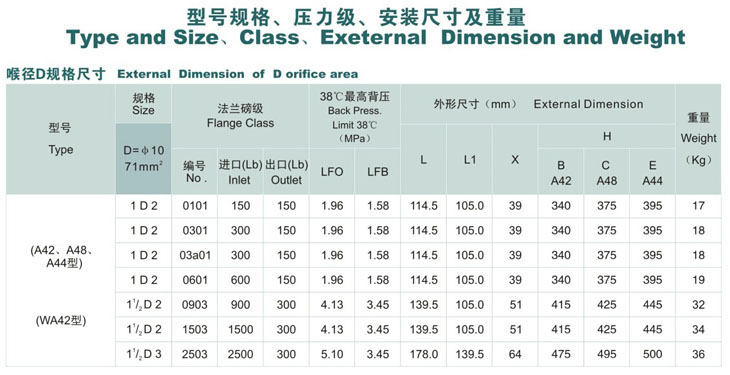

Code of throat diameter

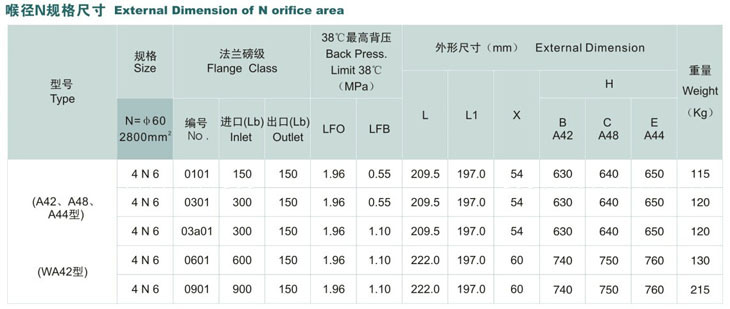

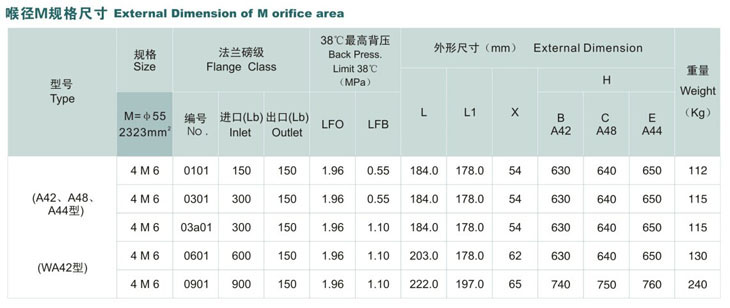

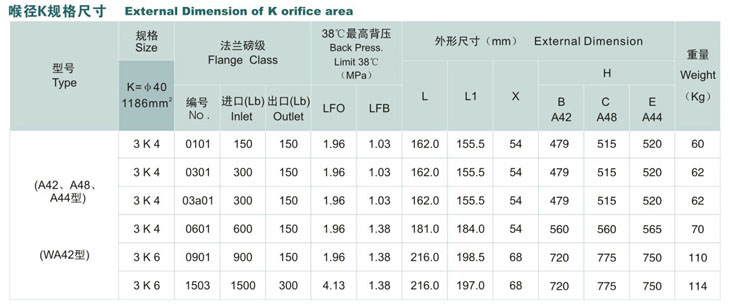

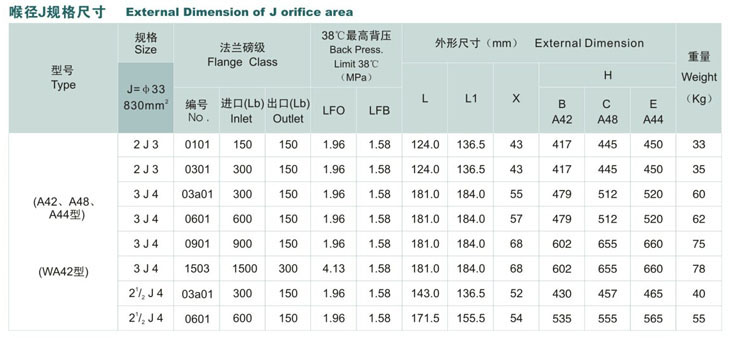

| Code | Diameter | Code | Diameter |

| D | 10 | L | 50 |

| E | 13 | M | 55 |

| F | 16 | N | 60 |

| G | 20.5 | P | 72 |

| H | 26 | Q | 96 |

| J | 33 | R | 115 |

| K | 40 | T | 148 |