Description

GENERAL CONSTRUCTION

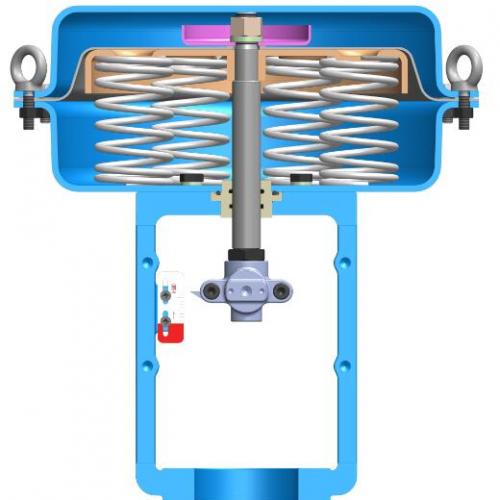

Trunnion ball valves have the obturator bounded by trunnions which do not allow axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to sizes and pressures. Fully welded constructions, both flanged or with welded ends, are preferable solution when no maintenance is required on above ground or below ground (buried) installations and allows a real 0 leakage feature.MATERIALS OF CONSTRUCTION

Low Temperature and Low Alloy Carbon SteelStainless steel, Duplex and Super Duplex

Nickel alloys

STANDARD FEATURES

Construction: Fully welded body

Port: Reduced bore, full bore or fully piggable

Stem retention: Anti blow-out stem

Leakage rate: ISO 5208 rate A soft seated, rate D metal seated

Antistatic device: Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function.

Pressure relief :Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats)

Sealing: Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request)

Metal seated with Tungsten or Chrome Carbide coatings

Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate

Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request

Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request.

Drain: Drilled and threaded connections for all sizes

Vent: Drilled and threaded vent connections for sizes ≥ DN150 (6") < DN150 upon request

Stem grease injectors: Included for all sizes

Seat grease injectors: Included for sizes ≥ DN150 (6"), < DN150 upon request

Lifting points: Included for sizes ≥ DN150 (6") or on valves of 250 kg min

Support feet: Included for sizes ≥ DN150 (6") or on valves of 250 kg min

Stem extension:Available upon request

Pups pieces :Available upon request

Valve operation: Lever, Gear box or Actuator with position indicator and locking device

Material testing: Pressure containing & controlling parts to EN 10204 3.1

Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156

Non-destructive testing (NDT) to API 6D, ASME B16.34

Welding & NDT according to ASME IX; WPS, PQR, WPQ as per project requirements

Valve testing: Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request)

TECHNICAL DATA

Design: API 6D, API 6DSS, ASME B16.34, ISO 14313, ISO 17292Design pressure: ASME B16.34, EN 1092-1, ISO 17292

Body wall thickness ASME B16.34, ASME VIII Div. I, ISO 17292

Face to Face: API 6D, ASME B16.10 Long pattern

Temperature range: -50° to 200°C (-58° to 392°F)

Pressures range: PN20 (ANSI 150) to PN420 (ANSI 2500)

Size range: DN15 (1/2") to DN1400 (56")

End connections: ASME B16.5 ≤ DN600 (24") Flanged RF,FF,RTJ

MSS-SP-44 = DN550 (22") Flanged RF,FF,RTJ

ASME B16.47 A ≥ DN650 (26") Flanged RF,FF,RTJ

ASME B16.25 Butt-Weld BW

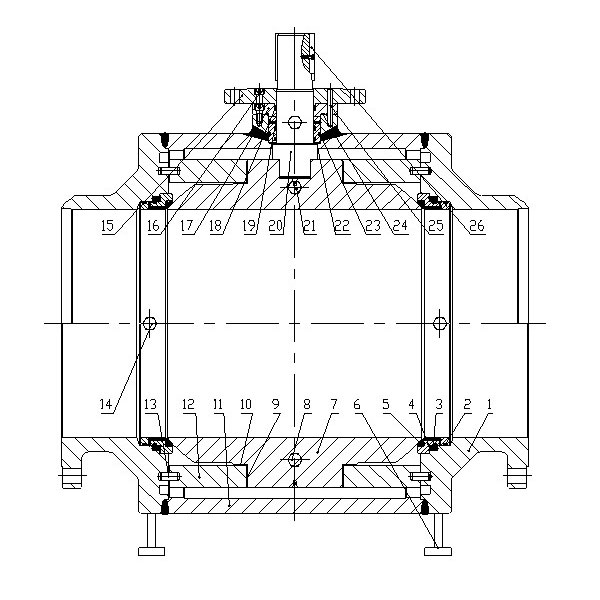

|

No. |

Parts Name |

Materials |

|

|

Carbon Steel |

Low Tem. Steel |

||

|

1 |

Body side section |

ASTM A105 |

ASTM A350-LF2/LF3 |

|

2 |

O-ring |

Viton |

Viton |

|

3 |

Spring |

17-7PH/Inconel |

17-7PH/Inconel |

|

4 |

Seat ring |

ASTM A105+ENP |

ASTM A350-LF2+ENP |

|

5 |

Seat |

PTFE/RPTFE/NYLON |

PTFE/RPTFE/NYLON |

|

6 |

Support |

Carbon Steel |

Carbon Steel |

|

7 |

Ball |

ASTM A105+ENP |

ASTM A350-LF2+ENP |

|

8 |

Drain plug |

Carbon Steel |

Carbon Steel |

|

9 |

Sliding bearing |

304+PTFE |

304+PTFE |

|

10 |

Sliding washer |

304+PTFE |

304+PTFE |

|

11 |

Body mid section |

ASTM A105 |

ASTM A350-LF2/LF3 |

|

12 |

Support plate |

ASTM A105 |

ASTM A350-LF2/LF3 |

|

13 |

Pin |

ASTM A276-304 |

ASTM A276-304 |

|

14 |

sealant injection |

Carbon Steel |

Carbon Steel |

|

15 |

Gland |

ASTM A105 |

ASTM A350-LF2/LF3 |

|

16 |

Screw |

ASTM A193-B7/B7M |

ASTM A320-L7 |

|

17 |

Packing case |

ASTM A105 |

ASTM A350-LF2 |

|

18 |

Fire safe packing |

Graphite |

Graphite |

|

19 |

Spacing collar |

ASTM A105+ENP |

ASTM A350-LF2/LF3+ENP |

|

20 |

Stem |

ASTM A182-F6a |

ASTM A182-F304 |

|

21 |

Release valve |

Carbon Steel |

Carbon Steel |

|

22 |

Thrust washer |

304+PTFE |

304+PTFE |

|

23 |

O-ring |

Viton |

Viton |

|

24 |

Gasket |

304+Graphite |

304+Graphite |

|

25 |

Pin |

ANSI 1045 |

ANSI 1045 |

|

26 |

Key |

ANSI 1045 |

ANSI 1045 |