Description

Self Actuated Temperature Control Valve for Steam Hot Water

Self actuated temperature control valve consists of two parts: temperature sensor and globe valve.And self operated temperature control valve does not require external energy,and uses the principle of liquid thermal expansion and liquid incompressibility to achieve automatic control.The liquid expansion in the temperature sensor is uniform, so the self operated temperature control valve is proportional control.

The self actuated temperature control valve working principle:

According to the action type and application, the self operated temperature control valve is divided into heating type,cooling type and mixing(/diverting) type.Put the temperature sensor into the medium that needs to control the temperature.

(1) When the temperature of the medium rises, the liquid in the sensor expands, the force overcomes the spring thrust, pushes the valve plug downward, and the valve tends to be closed, thereby reducing the flow rate of the heat medium.

(2) When the medium temperature is lower than the set value, the temperature sensitive liquid shrinks, and the spring pushes the valve plug to open, increasing the flow rate of the heat medium, so that the temperature of the controlled medium tends to rise. The cycle is repeated so that the temperature value of the controlled medium is always within the allowable range of the set temperature.

The Features of Self Actuated Temperature Control Valve:

1. The self actuated temperature control valve is small in size, light in weight and easy to install.

2. Self operated temperature control valve has a wide range of applications,such as steam,hot water,hot oil,cooling water,etc.

3. Accurate and reliable, long service life, easy temperature adjustment.

4. Automatic adjustment by the principle of liquid thermal expansion and liquid incompressibility.

5. The liquid expansion in the sensor is uniform expansion.

6. Control action type of self actuated temperature control valve is proportional control.

Technical Parameters of Self Operated Temperature Control Valve:

1.Nominal diameter:DN15~DN200;

2.Nominal pressure:PN16,PN25;

3.Valve body type:single-seat,double-seated,cage guide,three way;

3.Suitable medium:steam,hot water,hot oil,cooling water,etc;

4.Application medium temperature:-20℃~350℃;

5.Temperature control range:0~70℃/50~120℃/100~170℃/150~220℃/200~270℃;

6.Allowed overload value:add 50℃ to the each temperature control range above;

7.Ambient temperature:-40℃~+80℃;

8.Adjustment accuracy:±5%;

9.Pipe length:3.5~4.5m,and if you have special requirements,please specify it.

10.Pressure balancing component: springs,bellows.

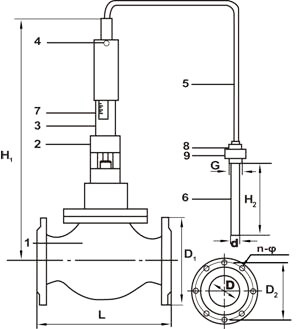

Dimensions of Self Actuated Temperature Control Valve:

| Size | H1 | D1 | D | D2 | L | d | G | H2 | n-Φ |

| DN32 | 555 | 135 | 32 | 100 | 180 | 25 | 1-1/4″ | 180 | 4-Φ18 |

| DN40 | 570 | 145 | 40 | 110 | 200 | 25 | 1-1/4″ | 180 | 4-Φ18 |

| DN50 | 610 | 160 | 50 | 125 | 230 | 25 | 1-1/4″ | 280 | 4-Φ18 |

| DN65 | 635 | 180 | 65 | 145 | 290 | 25 | 1-1/4″ | 280 | 4-Φ18 |

| DN80 | 680 | 195 | 80 | 160 | 310 | 25 | 1-1/4″ | 280 | 8-Φ18 |

| DN100 | 720 | 215 | 100 | 180 | 350 | 25 | 1-1/4″ | 280 | 8-Φ18 |

| DN125 | 760 | 245 | 125 | 210 | 395 | 25 | 1-1/4″ | 380 | 8-Φ18 |

| DN150 | 800 | 280 | 150 | 240 | 470 | 25 | 1-1/4″ | 380 | 8-Φ23 |

| DN200 | 950 | 335 | 200 | 300 | 550 | 25 | 1-1/4″ | 480 | 12-Φ22 |

| DN250 | 985 | 405 | 250 | 355 | 640 | 25 | 1-1/4″ | 480 | 12-Φ22 |

Note: the unit is mm and the size is for PN16.

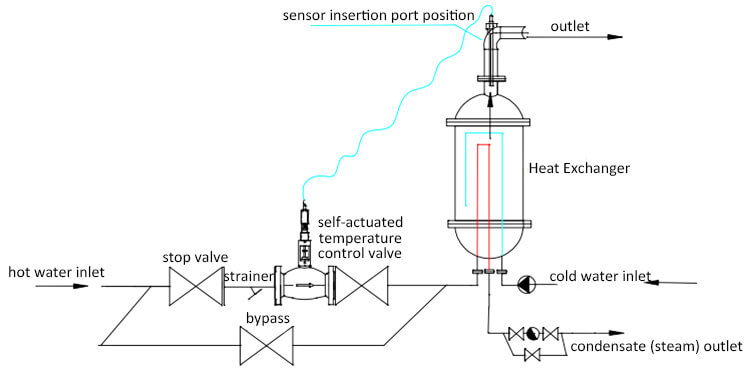

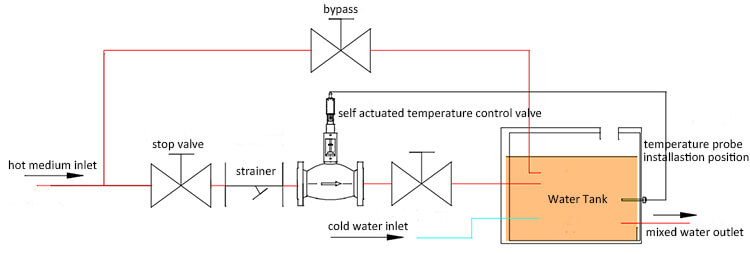

Application Example of Self-operated Temperature Control Valve:

Taking steam or high-temperature water as an example, steam or high-temperature water heats the cold water to the required temperature in the heater. Shut-off valves are installed before and after the temperature control valve for maintenance or stop heating and cut off the steam ( or high temperature water) flowing through the regulating valve. The bypass is used when the regulator valve is faulty or overhauled, and the bypass is closed during normal operation. Thermostat controller is installed on the outlet of the hot water.

Installation Instructions of Self Actuated Temperature Control Valve:

1. Valve body installation

(1) The valve body should be installed horizontally at the inlet of the primary heat medium with the valve stem facing up and ensure that the actuator is installed vertically.

(2) Strainer should be installed before the self operated temperature control valve, and the accuracy should be as high as possible.

(3) Install the manual stop valve before and after self actuated temperature control valve, install the bypass on the valve side, and install the manual stop valve.

(4) The optimum working range of upstream steam is 0.3~0.7Mpa.

(5) The standard installation method is as shown:

2.Temperature probe installation

The temperature probe is mounted near the heat exchanger outlet or on the water outlet pipe. Do not damage the valve stem when installing the self operated temperature control valve. The temperature probe must be tightly mounted to the wire holder and ensure no leakage or shedding.

3.Actuator installation

(1) The guide pipe is naturally unfolded in the direction of capillary winding.

(2) Press the stem firmly to the bottom. If the force is not enough, please use the auxiliary tools.

(3) Install the actuator assembly on the valve body and tighten the nut to ensure that the heat insulation frame is fastened to the valve body, that is, the installation work of self actuated temperature control valve is completed.