Description

PTFE/PFA/FEP Lined Ball Valve

The full port flow path increases the CV of PFA Lined Ball Valve and decreases pressure loss resulting in a more efficient piping system. The one piece ball and stem design of our PFA Lined Ball Valve results in higher pressure & temperature rating and reduces the potential of ball or stem failure. Our PFA Lined Ball Valve facilitates universal ISO 5211 mounting dimensions and its quarter turn design simplify valve Actuation.

Attributes :

- Meet design specification as per B 16.34 / Face to Face as per ANSI B 16.10 / Flange dimensions as per B 16.5.

- Testing Standard as per BS EN 12266-1 / DIN -EN 588 -1

- Lining Standard as per ASTM F 1545

- A two -piece Full port PFA lined ball valve which offers high safety factor, high stability, rigidity and eliminates a potential leakage path

- A Ball to stop or start the flow of fluid

- Live loading packing system provided by PTFE “V“Rings in the deep stuffing box and by the molded liner

- Antistatic device protects against potentially dangerous electrostatic discharges

- Labyrinth like seal with increased surface loading by means of molded sealing lips

- Full lining thickness in the sealing groove provides security against permeating media

- Fish -Hook groove anchoring lining suitable to vacuum application

- PTFE Cushion seat rings and easily replaceable

- Tight even during frequent cycles of hot and cold effected by almost metal to metal flange contact in the circumference area close to the flange media

- The body piece position themselves properly by means of the cup and cone shapes of each piece

- Epoxy coated body and stainless steel hardware provide minimum atmospheric corrosion protection

- As an alternative to valves made of exotic special metals

Technical Data :

- Size Range : 1”NB to 8”NB

- Pressure Range : 0 to 10 Bar

- Temperature Range : -60℃ to +200℃

- Vacuum resistance : Full (Vacuum up to 16 Bar)

- Tightness : BS-EN-12266-1

- Leakage Rate : D, Test Media: Gas

- Leakage Class : as per Class VI shut off.

- Body Material : S.G. Iron (NOD CI) / CF8 / CF8M / CD4MCu + Lined

- Lining Material : FEP / PFA / PVDF / Ceramic / Antistatic PFA Lining

- Spark Test : Thick liner 100% Inspected at 20 KVA

Optional Features :

- Ball available in aluminum oxide for abrasive application

- Extended stem design on request

- 3- Way Lined Ball design available on request

- Lined Valves with Automation available on request

- Available with equal percentage V Ball valves

- Large sizes on request

- Locking arrangement on request

| No. | Part | Cast Iron | Carbon steel | Stainless steel | Stainless steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Body / Bonnet | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Ball / Stem | WCB | CF8 | CF8M | CF3 | CF3M | |

| 3 | Lining / Seat | PCTEF(F3),FEP(F46),PFA( F4),PP,PO | |||||

| 4 | Gland | WCB | CF8 | CF8M | CF3 | CF3M | |

| 5 | Packing | PTFE(F4) | PTFE(F4) | PTFE(F4) | |||

| 6 | Yoke | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | |||

| 7 | Bolt | 35 | Cr17Ni2 | 1Cr18Ni2 | |||

| 8 | Nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | |||

| 9 | Handle | WCB | WCB | WCB | |||

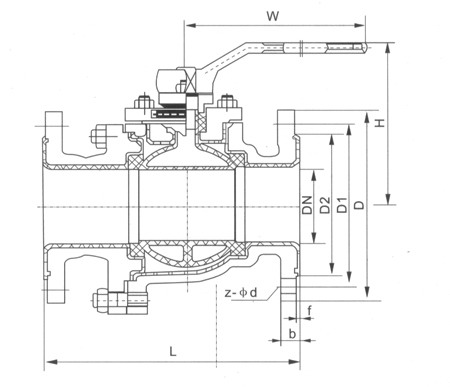

| Dimension |

| Size | L | D | D1 | D2 | f | b | Z-φd | |

| DN(mm) | NPS(inch) | PN1.0MPa | ||||||

| 15 | 1/2 | 130 | 95 | 65 | 45 | 2 | 14 | 4-φ14 |

| 20 | 3/4 | 140 | 105 | 75 | 55 | 2 | 16 | 4-φ14 |

| 25 | 1 | 150 | 115 | 85 | 65 | 2 | 16 | 4-φ14 |

| 32 | 5/4 | 165 | 135 | 100 | 78 | 2 | 18 | 4-φ18 |

| 40 | 3/2 | 180 | 145 | 110 | 85 | 3 | 18 | 4-φ18 |

| 50 | 2 | 200 | 160 | 125 | 100 | 3 | 20 | 4-φ18 |

| 65 | 5/2 | 220 | 180 | 145 | 120 | 3 | 20 | 4-φ18 |

| 80 | 3 | 250 | 195 | 160 | 135 | 3 | 22 | 4-φ18 |

| 100 | 4 | 280 | 215 | 180 | 155 | 3 | 22 | 8-φ18 |

| 125 | 5 | 320 | 245 | 210 | 185 | 3 | 24 | 8-φ18 |

| 150 | 6 | 360 | 280 | 240 | 210 | 3 | 24 | 8-φ23 |

| 200 | 8 | 457 | 335 | 295 | 265 | 3 | 26 | 8-φ23 |

| 250 | 10 | 533 | 390 | 350 | 320 | 3 | 28 | 12-φ23 |

| PN1.6MPa | ||||||||

| 15 | 1/2 | 130 | 95 | 65 | 45 | 2 | 14 | 4-φ14 |

| 20 | 3/4 | 130 | 105 | 75 | 55 | 2 | 16 | 4-φ14 |

| 25 | 1 | 140 | 115 | 85 | 65 | 2 | 16 | 4-φ14 |

| 32 | 5/4 | 165 | 135 | 100 | 78 | 2 | 18 | 4-φ18 |

| 40 | 3/2 | 165 | 145 | 110 | 85 | 3 | 18 | 4-φ18 |

| 50 | 2 | 203 | 160 | 125 | 100 | 3 | 20 | 4-φ18 |

| 65 | 5/2 | 222 | 180 | 145 | 120 | 3 | 20 | 4-φ18 |

| 80 | 3 | 241 | 195 | 160 | 135 | 3 | 22 | 8-φ18 |

| 100 | 4 | 305 | 215 | 180 | 155 | 3 | 24 | 8-φ18 |

| 125 | 5 | 356 | 245 | 210 | 185 | 3 | 26 | 8-φ18 |

| 150 | 6 | 394 | 280 | 240 | 210 | 3 | 28 | 8-φ23 |

| 200 | 8 | 457 | 335 | 295 | 265 | 3 | 30 | 12-φ23 |

Applications :

- Industrial Inorganic Chemicals

- Metal & Mining Industry

- Industrial Organic Chemicals

- Plant protective agent production

- Alkali’s & Chlorine

- Pulp, Paper & Wood

- Detergent production

- Water treatment

- Bromine Production

- Sulfur recovery

- Nitrogenous & Phosphorus Fertilizers

- Food Processing

- Pharmaceutical Preparation

- Sugar Industries

- Petroleum Refining

- Corn Industries