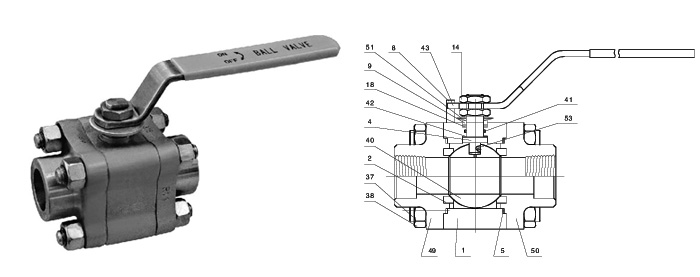

Description

Small Forged Ball Valve Stainless Steel F316L Soft Seated Reduced Bore SW / NPT 800LB

Description

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball's hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status.

Quick Details

1. Product: Forged Steel F316L 3PC Ball Valve SW / NPT

2. Design: BS5351

3. Size Range: 1/2” - 2"

4. Pressure Ratings: 800LB

5. Body materials: Stainless Steel A182 F316 / F316L

6. Trim: 316SS

7. Bore Type: Reduced Bore (RB)

8. Actuator: Lever

9. NACE MR0175

10. Three Piece (3 Pcs) Body

Features

1. Switch Indication of Hand Operated Ball Valve

As the moving parts of valve body, ball, stem and handle are an assembly unit. The head of valve stem is shaped a diploid, thus to easily distinguish whether valve is in the 'ON' position or 'OFF' position from handle position. When handle or stem diploid is in parallel with the pipe axis, valve is in 'ON' position; when handle or stem diploid is vertical to the pipe axis, valve is in 'OFF position.

2. Valve Locking Device

To prevent mis-operation, the fully opened or closed position of valve can be locked up, especially when valves are mounted outdoors or when valves are not allowed to be opened or closed by technical process. To prevent misoperation by other persons, it seems very important to have valve position locked up. Thereby, lockhole locating tab is designed if requested by users to meet the technological requirements of users.

3. Anti-Blowout Structure of Valve Stem

When medium passes through the valve, the pressure in valve body may possibly push the stem out, or when the valve is in repair, if there is pressure in the middle cavity, the stem or medium seems to easily blow out upon disassembling the valve, which can cause injuries to person. To prevent these possibilities, a dummy club is placed at the lower part of the stem. In this way, even if there is fire, packing and thrust bearing are burnt or packing is damaged due to other causes, the pressure of medium in valve body will make the dummy club of valve stem in close contact with the upper seal face of valve body, thus to prevent medium leaking out from the damaged packing position.

Description

1. Forged Steel Soft Seated Ball Valve Standards:

A. Design and manufacture: BS5351, MSS SP -118

B. Inspection and Test: API 598

C. Socket-weld dimension: ANSI B16.11

D. Screw thread dimension: ANSI B1.20.1

E. Face to face or End to ends: ASME B16.10

F. Pressure-temperature rating: ASME B16.34

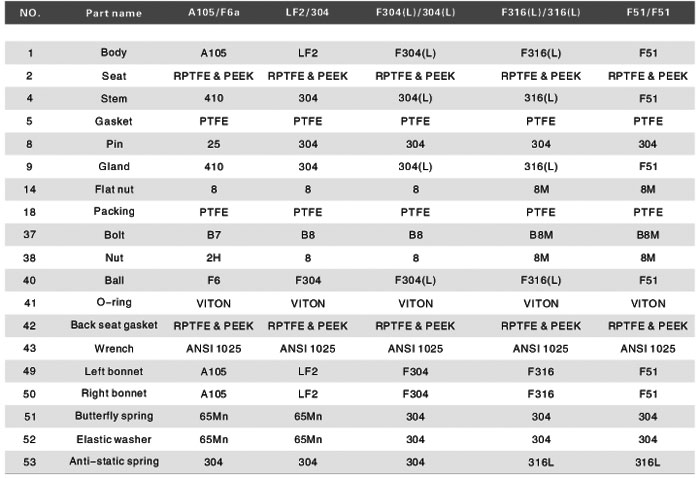

Standard material specification

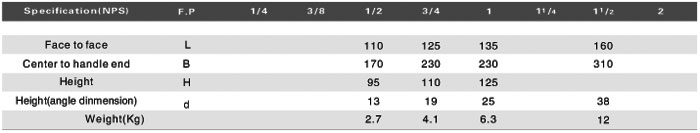

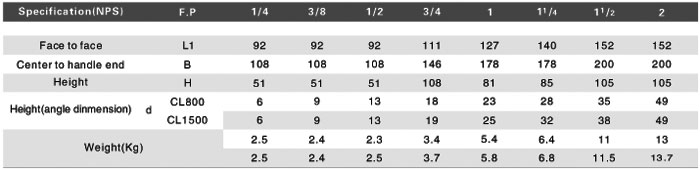

Dimension and weight for class 800# & 1500#

Dimension and weight for class 2500#