Description

JD745X multi-function pump control valve

Overview

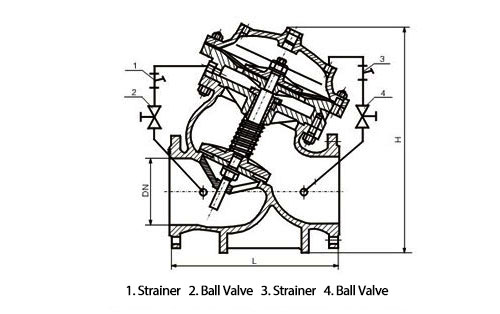

JD745X multi-function pump control valve is composed of main valve, regulating valve and nozzle system. The valve body adopts direct-flow valve body. The main valve control chamber is a diaphragm or piston type double control chamber structure. The control chamber is one more than the general hydraulic control valve. The control function of the main valve is increased, and the slow opening of the pump outlet is realized. Full open, slow close, cut-off and other multi-functional control, to achieve a valve, one-time regulation of the pump outlet multi-functional control.

The nozzle system of this product is controlled by a regulating valve. By setting the opening of the regulating valve, the required control parameters, such as the opening speed of the main valve, the slow closing speed and so on, can be easily realized.

Working principle

When the pump starts, the water pressure acts on the lower chamber of the main valve disc and the control chamber. This pressure opens the main valve. The water in the upper chamber of the control chamber is slowly discharged to the outlet through the control valve B, and the main valve opens slowly. Setting the opening of the regulating valve can get the opening speed of the suitable main valve. When the pump stops working, the inlet water pressure drops rapidly and closes most of the opening quickly under the self-weight and spring pressure, which prevents the remaining opening from slowly closing under the combined action of the water pressure in the upper chamber and the water pressure in the lower chamber.

Setting the opening and opening ratio of the regulating valve A and B can get the proper valve opening and closing speed.

Work characteristics

1. Prevent the water hammer effect is good, will slow open, check the speed of closure, slow shut and other elimination of water hammer technology integration, to prevent the pump does not start hammer and stop the pump backflow and water hammer on the water supply pipeline and pump damage.

2. Easy operation, no need to distribute another control system for the valve, the valve with the pump to open and stop automatically and in order to complete the control function. Proper control parameters can be obtained by setting control valve opening.

3, the valve body uses a full channel, DC, streamlined design. The hydraulic loss is small and the energy saving effect is good.

Functions and uses

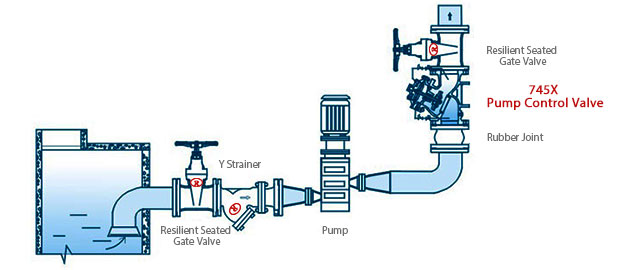

The valve is installed at the outlet end of the pump, and the functions of slow opening, full opening, quick closing and slow closing are realized sequentially.

This product is used in high-rise building water supply system and other water supply system pump outlet pipeline to prevent and weaken the water hammer water hammer when the pump is opened and closed, prevent water backflow to protect the pump, maintain pipeline safety.

Main technical parameters

|

Nominal Pressure (MPa) |

Shell Test (MPa) |

Sealing Test (MPa) |

Fluids |

Fluids Temp (°C) |

| 1.0 | 1.5 | 1.1 | Water | 0-80 |

| 1.6 | 2.4 | 1.76 | ||

| 2.5 | 3.75 | 2.75 |

Dimensions

| DN | L | D | D1 | n-d | H | ||||||

| 1.0MPa | 1.6 (MPa | 2.5 MPa | 1.0MPa | 1.6 MPa | 2.5 MPa | 1.0MPa | 1.6 MPa | 2.5 MPa | |||

| 50 | 205 | 165 | 165 | 165 | 125 | 125 | 125 | 4-18 | 4-18 | 4-18 | 293 |

| 65 | 216 | 185 | 185 | 185 | 145 | 145 | 145 | 4-18 | 4-18 | 8-18 | 328 |

| 80 | 250 | 200 | 200 | 200 | 160 | 160 | 160 | 8-18 | 8-18 | 8-18 | 364 |

| 100 | 320 | 220 | 220 | 235 | 180 | 180 | 190 | 8-18 | 8-18 | 8-22 | 418 |

| 125 | 365 | 250 | 250 | 270 | 210 | 210 | 220 | 8-18 | 8-18 | 8-22 | 481 |

| 150 | 415 | 285 | 285 | 300 | 240 | 240 | 250 | 8-22 | 8-22 | 8-26 | 543 |

| 200 | 500 | 340 | 340 | 360 | 295 | 295 | 310 | 8-22 | 12-22 | 12-26 | 673 |

| 250 | 605 | 395 | 405 | 425 | 350 | 355 | 370 | 12-22 | 12-26 | 12-26 | 792 |

| 300 | 698 | 445 | 460 | 485 | 400 | 410 | 430 | 12-22 | 12-26 | 12-30 | 927 |

| 350 | 787 | 505 | 520 | 555 | 460 | 470 | 490 | 16-22 | 16-26 | 16-30 | 957 |

| 400 | 914 | 565 | 580 | 620 | 515 | 525 | 550 | 16-26 | 16-30 | 16-33 | 1188 |

| 450 | 978 | 615 | 640 | 670 | 565 | 585 | 600 | 20-26 | 20-30 | 16-36 | 1218 |

| 500 | 978 | 670 | 715 | 730 | 620 | 650 | 660 | 20-26 | 20-33 | 20-36 | 1256 |

| 600 | 1150 | 780 | 840 | 845 | 725 | 770 | 770 | 20-30 | 20-36 | 20-39 | 1600 |

| 700 | 1300 | 895 | 910 | 960 | 840 | 840 | 875 | 2430 | 24-36 | 24-42 | 1750 |

| 800 | 1450 | 1015 | 1025 | 1085 | 950 | 950 | 990 | 2433 | 24-39 | 24-48 | 1900 |

Installation