Description

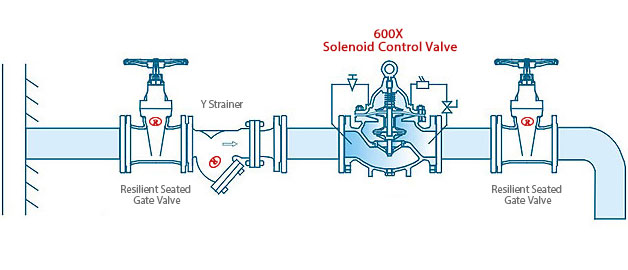

600X Solenoid Control Valve

Overview

600X Solenoid Control Valve is a kind of self-acting valve with electric-magnetic valve as pilot valve. It is used in automatic control of feeding system and industrial system and its control reaction is quick and precise. It opens or closes pipeline system according to the electric signal to reach remote control operation. It can be used in large-scale electric operation system instead of gate valve and butterfly valve. Its close speed is adjustable and it can close stably without any pressure fluctuation.

Electric-magnetic valve is of AC 220 V or DC 24V. It can be normally open or normally close according to the site condition.

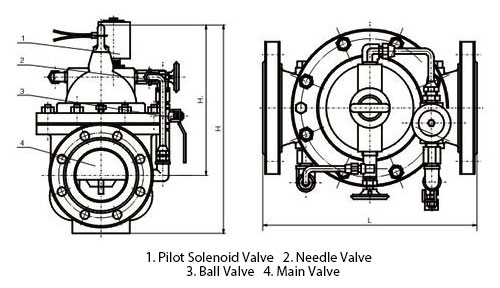

1. Small Ball Valve

2. Pilot Valve

3. Flow Controller

4. Needle Valve

Materials

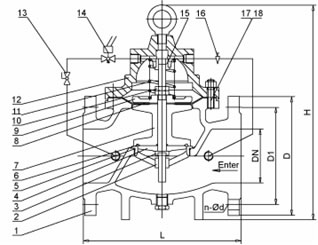

| Serial No. | Part | Material |

| 1 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 2 | Seat | 410 S.S. / SS 304 / SS 316 |

| 3 | Stem | 410 S.S. / SS 304 / SS 316 |

| 4 | O-ring washer | Cast Iron / WCB |

| 5 | O-ring | NBR |

| 6 | O-ring | NBR |

| 7 | Disc | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 8 | Diaphragm | Rubber |

| 9 | Diaphragm washer | Cast Iron |

| 10 | Nut | Bronze |

| 11 | Spring | Spring Steel |

| 12 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 13 | Ball valve | Bronze |

| 14 | Solenoid valve | Bronze |

| 15 | Pilot socket | Bronze |

| 16 | Needle valve | Bronze |

| 17 | Stud | Steel |

| 18 | Nut | Steel |

Dimensions

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 280 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | 1230 | 1300 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 | 780 | 895 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 | 840 | 910 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | |

| H | 342 | 342 | 342 | 395 | 395 | 405 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 1070 | 1135 | 1270 | 1460 | |

| H1 | 250 | 250 | 250 | 278 | 278 | 298 | 315 | 350 | 365 | 420 | 450 | 470 | 490 | 526 | 570 | 610 | 665 | 725 | 865 | |

Note: Either elastic seat ring sealed gate valve or butterfly valve can be selected in the schematic of installation. Recommend to select the butterfly valve in case of DN350

Installation