Description

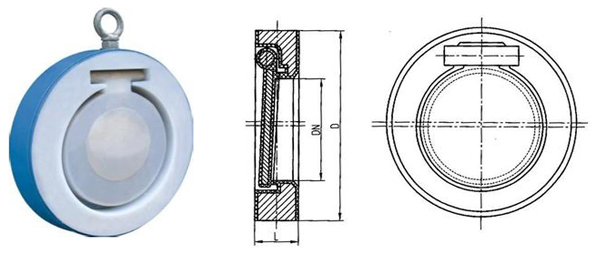

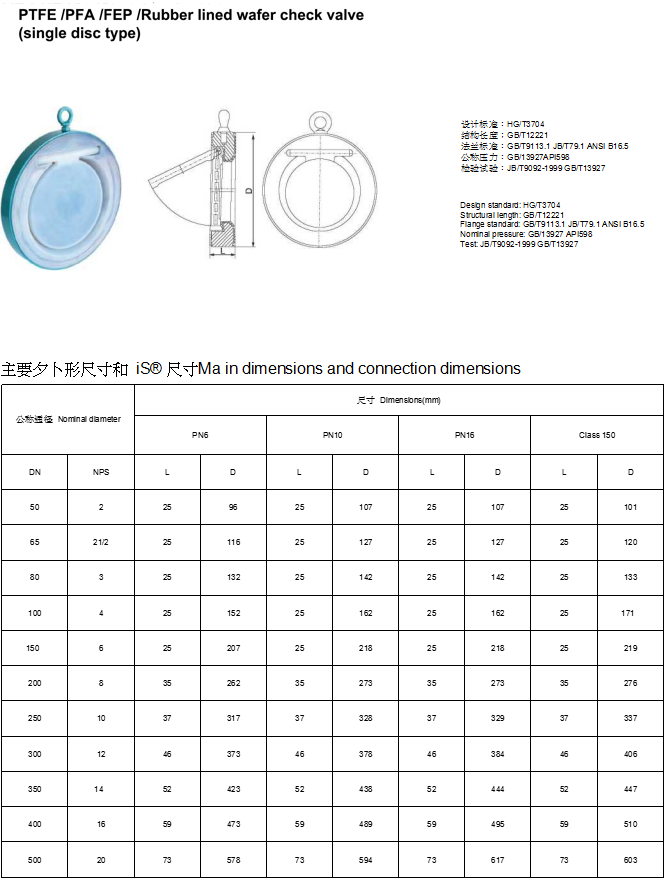

Rubber lined single plate check valve

Overview:Opening & closing parts rely on the flow of media and power to open or close, in order to prevent media backflow valve called check valve.Check valves belong to automatic valves, mainly used for one-way flow of media on the pipeline, only allow the media to flow in one direction, in order to prevent accidents.

Industries:

Acid Transfers, Caustic & Chlor- Alkali, Chemicals, Pharmaceuticals, Water Treatment

1.Standard Design

- Rubber lined single plate check valveare design in accordance with face to face dimension of GB/T 12235.

- Do not load the check valve in the pipeline. Large check valves should be supported independently from the pressure produced by

- the pipeline.

- When installing, pay attention to the direction of media flow should be consistent with the arrow direction of the valve body.

- Lifttype horizontal flap check valve shall be installed on horizontal pipe.

- Three sort of Check Valves: 1.Horizontal check valve, 2.Lifting vertical check valve 3.swing check valve,

- Lining Specifications:

- Lining Material

- We offer lining materials like Rubber -- NR, BR, IIR, CR, EPDM, NBR,CSPE, FKM, SI

Lining Thickness

- Min. 3.0mm

- Body liners & all wet parts are tested for spark at 15,000 Volts

- The body material is generally,Grey Cast Iron,Cast Ductile Iron,Cast Steel and alternatively