Description

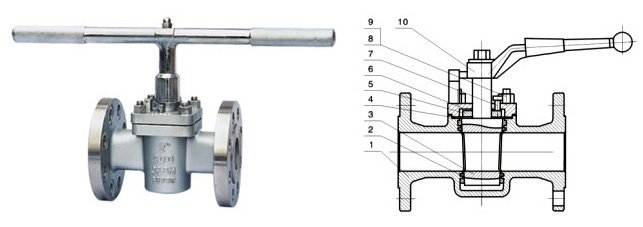

Sleeve Type Soft Seat Plug Valve

Sleeve type soft sealing plug valve (ANSI) is applicable to the cutting and connection of pipelines medium that are used in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc under nominal pressure of CLASS150~900LB, and working temperature of -29~180 celsius degree.Features

The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance.

Its sealing is realized by the sealing face around the sleeve. It has unique 360 degree metal edge for protection and fixing of the sleeve.

There is no cavity in the valve for accumulation of medium.

Metal edge provides the function of selfcleaning when the plug is rotated, applicable to the operation condition that is glutinous and apt to smudge.

Its characteristic doubledirection flow makes installation and use more convenient.

The materials of the pars and sizes of flanges can be reasonably configured according to the actual operation condition of the requirements of the customers, so as to meet the various needs of engineering.

Product Details

Design and Manufacture API599,API 6D

Face to face(end to end) ANSI B16.10

Flanged connection ANSIB16.5

Test and inspection API598,API6D

Standard Material specifications

|

NO.

|

Part name

|

Material

|

||||

|

A216 WCB

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

||

|

1

|

Body

|

A216 WCB

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

|

2

|

sleevd

|

PTFE/RPTFE

|

||||

|

3

|

Plug

|

A182 F6a

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

|

4

|

Gasket

|

Flexible graphite+stainless steel PTFE

|

||||

|

5

|

Adjusting gasket

|

A182 F6a

|

A182 F304

|

A182 F316

|

A182 F304L

|

A182 F316L

|

|

6

|

Cover

|

A216 WCB

|

A351 CF8

|

A351 CF8

|

A351 CF3

|

A351 CF3M

|

|

7

|

Adjusting bolt

|

A193 B7

|

A193 B8

|

A193 B8M

|

A193 B8M

|

A193 B8M

|

|

8~9

|

Bolt/nut

|

B7/2H

|

B8/8

|

B8M/8M

|

B8M/8M

|

B8M/8M

|

|

10

|

Wrench

|

AsTM A105/A216 WCB

|

||||

Dimensions(mm) and Weights(Kg)

|

Class 150Lb

|

||||||||||||||||

|

size

|

inch

|

1/2

|

3/4

|

1

|

1-1/4

|

1-1/2

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

|

L-RF

|

mm

|

108

|

117

|

127

|

140

|

165

|

178

|

190

|

203

|

229

|

254

|

267

|

292

|

330

|

356

|

381

|

|

H

|

mm

|

110

|

115

|

115

|

135

|

140

|

150

|

165

|

180

|

380

|

460

|

520

|

580

|

620

|

680

|

760

|

|

W

|

mm

|

175

|

175

|

175

|

220

|

280

|

305

|

350

|

405

|

300

|

300

|

320

|

320

|

350

|

380

|

450

|

|

Weight

|

Kg

|

8.5

|

9.5

|

10.5

|

12

|

14

|

18

|

22

|

26

|

40

|

60

|

70

|

130

|

219

|

381

|

570

|

|

Class 300Lb

|

||||||||||||||||

|

size

|

inch

|

1/2

|

3/4

|

1

|

1-1/4

|

1-1/2

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

|

L-RF,BW

|

mm

|

140

|

152

|

165

|

178

|

190

|

216

|

241

|

283

|

305

|

381

|

403

|

419

|

457

|

502

|

762

|

|

H

|

mm

|

110

|

115

|

115

|

135

|

140

|

150

|

165

|

180

|

380

|

460

|

520

|

580

|

620

|

680

|

760

|

|

W

|

mm

|

175

|

175

|

175

|

220

|

280

|

305

|

350

|

405

|

300

|

300

|

320

|

320

|

350

|

380

|

450

|

|

Weight

|

Kg

|

9.5

|

10.5

|

12

|

14

|

16

|

20

|

24

|

29

|

53

|

75

|

85

|

185

|

230

|

390

|

550

|

|

Class 600Lb

|

||||||||||||||||

|

size

|

inch

|

1/2

|

3/4

|

1

|

1-1/4

|

1-1/2

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

|

L-RF,BW

|

mm

|

165

|

190

|

216

|

229

|

241

|

292

|

330

|

356

|

432

|

508

|

559

|

660

|

787

|

838

|

889

|

|

H

|

mm

|

110

|

115

|

115

|

135

|

140

|

150

|

165

|

180

|

380

|

460

|

520

|

580

|

620

|

680

|

760

|

|

W

|

mm

|

175

|

175

|

175

|

220

|

280

|

305

|

350

|

405

|

300

|

300

|

320

|

320

|

350

|

380

|

450

|

|

Weight

|

Kg

|

11

|

13

|

17

|

20

|

23

|

27

|

31

|

36

|

72

|

98

|

141

|

245

|

330

|

515

|

710

|

|

Class 900Lb

|

||||||||||||||||

|

size

|

inch

|

1/2

|

3/4

|

1

|

1-1/4

|

1-1/2

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

|

L-RF

|

mm

|

229

|

229

|

254

|

279

|

305

|

368

|

419

|

381

|

457

|

559

|

610

|

737

|

838

|

965

|

1029

|

|

H

|

mm

|

110

|

115

|

115

|

135

|

140

|

150

|

165

|

180

|

380

|

460

|

520

|

580

|

620

|

680

|

760

|

|

W

|

mm

|

175

|

175

|

175

|

220

|

280

|

305

|

350

|

405

|

300

|

300

|

320

|

320

|

350

|

380

|

450

|

|

Weight

|

Kg

|

13

|

16

|

21

|

24

|

28

|

32

|

40

|

47

|

91

|

117

|

165

|

285

|

420

|

610

|

86

|