Description

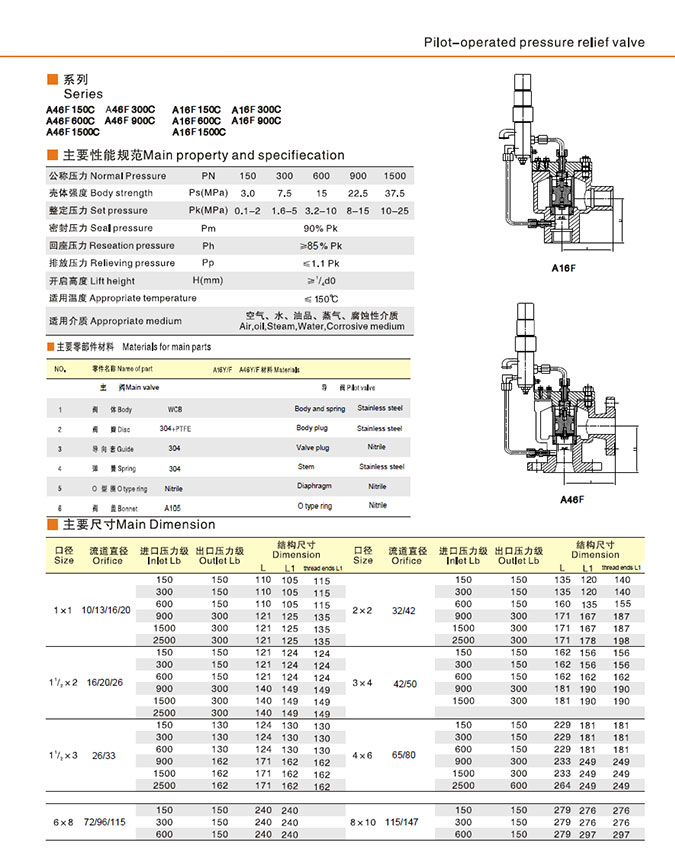

Pilot Operated Safety Relief Valve

Applicable Standard

- Design Standard: API 520

- Performance Standard: API 526

- Seat Tightness Test: API 527

- End Connection: Screwed To ASME B 1.20.1, Socket Weld To ASME B 16.11, Butt Weld To ASME B16.25, Flanged To ASME B 16.5

Product Applications

The pilot operated safety relief valve is used for safety purpose in Oil and Gas industries. The pilot operation make these valves ideal for industrial applications in Oil and Gas.

Product Specification

- Size: 1" X 2" to 8" X 10"

- Rating: 150# X 150# to 2500# X 300#

- Pilot type: Pop action, Relief action

- End Connection: Flange End, Screwed end

- Blow Down Pressure: 10% To 15% Less Then Of The Set Pressure.

- Application : Air, Gas, Liquid

- Hydrostatic Test Pressure: 1.5 Times The Set Pressure

- Overpressure: 10% To 21% Of The Set Pressure

- Orifice Designation: As per API

- Material: WCB, WC1, WC6, WC9, LCB, LCC, LC3, C5, C12, CF8, CF8M, CF3, CF3M,CF8C, CN7M, CD4MCu, Inconel, Duplex steel 4A, 5A, 6A, aluminium bronze, hastelloy c

Product Features

- Pilot Sensing Element

- Full Lift Pop Type Design

- Full Lift Modulating Type Design

- Stellited Nozzle & Disc Seating Area

- Floating Type Balance Seat Design

- Piston Op. Pilot Design For Pop Action

- Diaph. Op. Pilot Design For Modulating